Arụmọrụ nke ihe mkpuchi na-emetụta kpọmkwem ogo, arụmọrụ nhazi na oke ojiji nke waya na waya. Arụmọrụ nke ihe mkpuchi na-emetụta kpọmkwem ogo, arụmọrụ nhazi na oke ojiji nke waya na waya.

1.Waya na eriri polyvinyl chloride PVC

Polyvinyl chloride (nke a na-akpọ ugbu a:PVC) ihe mkpuchi bụ ngwakọta ebe a na-etinye ihe na-eme ka ihe kwụsie ike, ihe na-eme ka plastik, ihe na-egbochi ire ọkụ, ihe na-eme ka mmanụ na ihe mgbakwunye ndị ọzọ dị na ntụ ntụ PVC. Dịka ngwa dị iche iche na ihe achọrọ maka waya na eriri si dị, a na-agbanwe usoro ahụ dịka o kwesịrị. Mgbe ọtụtụ iri afọ nke mmepụta na ojiji gasịrị, teknụzụ mmepụta na nhazi nke PVC aghọọla nke tozuru oke. Ihe mkpuchi PVC nwere ọtụtụ ngwa n'ọhịa nke waya na eriri ma nwee njirimara pụrụ iche nke ya:

A. Teknụzụ mmepụta ihe a bụ nke tozuru okè, ọ dị mfe ịmepụta ma hazie. Ma e jiri ya tụnyere ụdị ihe mkpuchi waya ndị ọzọ, ọ bụghị naanị na ọ nwere ọnụ ahịa dị ala, kamakwa ọ nwere ike ijikwa ọdịiche agba, na-egbuke egbuke, mbipụta, arụmọrụ nhazi, ịdị nro na ike nke elu waya ahụ, njikọta nke onye na-eduzi ya, yana ihe onwunwe mekaniki na anụ ahụ na ihe onwunwe eletriki nke waya ahụ n'onwe ya.

B. O nwere ezigbo arụmọrụ nke na-egbochi ire ọkụ, yabụ waya ndị a na-ekpuchi PVC nwere ike iru ọkwa nke na-egbochi ire ọkụ nke ụkpụrụ dị iche iche kwadoro.

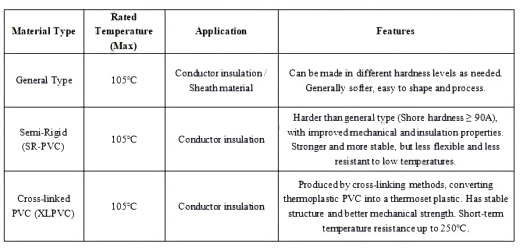

C. Banyere iguzogide okpomọkụ, site na imeziwanye na imeziwanye usoro ihe eji eme ihe, ụdị mkpuchi PVC a na-ejikarị eme ihe ugbu a gụnyere ụdị atọ ndị a:

Maka voltaji a na-enye ọkwa ya, a na-ejikarị ya eme ihe n'ọkwa voltaji dị na 1000V AC na n'okpuru ya, a pụkwara iji ya mee ihe n'ọtụtụ ụlọ ọrụ dịka ngwa ụlọ, ngwa na mita, ọkụ, na nkwukọrịta netwọk.

PVC nwekwara ụfọdụ ihe ndọghachi azụ ndị na-egbochi ojiji ya:

A. N'ihi oke chlorine ya, ọ ga-ewepụta nnukwu anwụrụ ọkụ mgbe ọ na-ere ọkụ, nke nwere ike ibute iku ume, imetụta anya, ma mepụta ụfọdụ ihe ndị na-akpata kansa na gas HCl, na-emebi gburugburu ebe obibi nke ukwuu. Site na mmepe nke teknụzụ mmepụta ihe mkpuchi halogen dị ala, iji nwayọọ nwayọọ dochie mkpuchi PVC aghọwo ihe a na-apụghị izere ezere na mmepe nke eriri waya.

B. Ihe mkpuchi PVC nkịtị anaghị eguzogide asịd na alkalis, mmanụ ọkụ, na ihe mgbaze organic. Dịka ụkpụrụ kemịkalụ nke ihe mgbaze dịka ihe mgbaze si dị, waya PVC na-adịkarị mfe imebi ma gbawaa n'ebe a kpọtụrụ aha. Agbanyeghị, n'ihi arụmọrụ nhazi ya dị mma yana ọnụ ala dị ala. A ka na-eji eriri PVC eme ihe n'ọtụtụ ebe na ngwa ụlọ, ihe ọkụ, ngwa igwe, ngwa na mita, nkwukọrịta netwọk, waya ụlọ na ubi ndị ọzọ.

2. Waya na eriri polyethylene ejikọtara ọnụ

PE ejikọtara ọnụ (nke a ga-akpọ ugbu aXLPE) bụ ụdị polyethylene nke nwere ike ịgbanwe site na nhazi molekul kwụ ọtọ gaa na nhazi atọ nwere akụkụ atọ n'okpuru ọnọdụ ụfọdụ n'okpuru ọrụ nke radieshon ike dị elu ma ọ bụ ihe ndị na-ejikọ ibe ha. N'otu oge ahụ, ọ na-agbanwe site na thermoplastic gaa na plastik thermosetting na-enweghị ike ịgbaze.

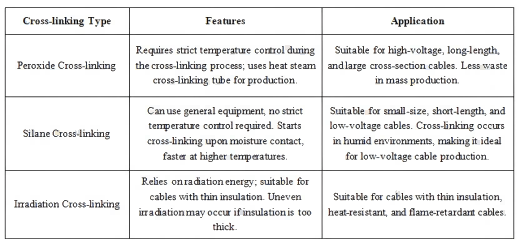

Ugbu a, n'iji mkpuchi waya na waya eme ihe, e nwere ụzọ atọ isi jikọta ihe:

A. Njikọta Peroxide: Ọ gụnyere iji resin polyethylene na njikọta ya na ihe ndị na-ejikọ njikọ kwesịrị ekwesị na ihe ndị na-egbochi ọrịa, wee tinye ihe ndị ọzọ dịka ọ dị mkpa iji mepụta ihe ndị na-ejikọta ngwakọta polyethylene nwere ike ijikọ. N'oge usoro mwepụta ahụ, njikọ njikọta na-eme site na ọkpọkọ steam na-ekpo ọkụ.

B. Njikọta Silane (njikọ mmiri ọkụ): Nke a bụkwa ụzọ njikọ kemịkalụ. Isi usoro ya bụ ijikọ organosiloxane na polyethylene n'okpuru ọnọdụ ụfọdụ, a

na ogo njikọ dị n'etiti ha nwere ike iru ihe dịka 60%.

C. Njikọta site na ọkụ eletrik: Ọ na-eji ụzarị ike dị elu dịka ụzarị R, ụzarị alpha, na ụzarị elektrọn mee ka atọm carbon dị na polyethylene macromolecules rụọ ọrụ ma mee ka njikọ dị n'etiti ha. Ụzarị ike dị elu nke a na-ejikarị na waya na waya bụ ụzarị elektrọn nke ihe na-eme ka ọkụ eletrik na-emepụta. Ebe ọ bụ na njikọ a dabere na ike anụ ahụ, ọ bụ nke njikọ anụ ahụ.

Ụzọ njikọta atọ dị iche iche dị n'elu nwere njirimara na ojiji dị iche iche:

Ma e jiri ya tụnyere thermoplastic polyethylene (PVC), mkpuchi XLPE nwere uru ndị a:

A. O meela ka iguzogide mgbanwe okpomọkụ dịkwuo mma, meziwanye ihe ndị dị na igwe n'oge okpomọkụ dị elu, ma melite iguzogide mgbawa nrụgide gburugburu ebe obibi na ịka nká okpomọkụ.

B. O meela ka ike kemịkalụ na iguzogide ihe mgbaze dịkwuo mma, belata mmiri oyi, ma nọgide na-arụ ọrụ eletriki mbụ. Okpomọkụ ọrụ ogologo oge nwere ike iru 125℃ na 150℃. Waya na eriri polyethylene nke ejikọtara na njikọ na-eme ka iguzogide obere sekit dịkwuo mma, iguzogide okpomọkụ obere oge ya nwekwara ike iru Na 250℃, maka waya na eriri ndị nwere otu ọkpụrụkpụ, ikike ibu polyethylene nke ejikọtara na njikọ dị ugbu a karịrị nke ahụ.

C. O nwere ezigbo ihe eji arụ ọrụ, mmiri anaghị amịpụta, ọ naghịkwa eguzogide radieshon, ya mere a na-ejikarị ya eme ihe n'ọtụtụ ebe. Dịka ọmụmaatụ: waya njikọ dị n'ime maka ngwa eletriki, ụzọ moto, ụzọ ọkụ, waya njikwa akara voltaji dị ala maka ụgbọala, waya locomotive, waya na waya maka ụgbọ ala ụgbọ oloko, waya nchekwa gburugburu ebe obibi maka ogbunigwe, waya mmiri, waya maka itinye ike nuklia, waya voltaji dị elu maka TV, waya voltaji dị elu maka ịgba ọkụ X-RAY, na waya na waya nnyefe ike, wdg.

Waya na eriri XLPE nke ejiri mkpuchi kpuchie nwere uru dị ukwuu, mana ha nwekwara ụfọdụ ọghọm dị n'ime ha nke na-egbochi ojiji ha:

A. Arụmọrụ njikọ na-adịghị mma nke na-anaghị eguzogide okpomọkụ. Mgbe a na-ahazi ma na-eji waya ndị karịrị okpomọkụ ha, ọ dị mfe ka waya ndị ahụ rapara n'ahụ ibe ha. N'ọnọdụ ndị siri ike, ọ nwere ike ibute mmebi mkpuchi na obere sekit.

B. Nguzogide okpomọkụ adịghị mma. Mgbe okpomọkụ karịrị 200℃, mkpuchi waya na-adị nro nke ukwuu. Mgbe a na-amanye ha ma ọ bụ kụọ ha n'ike, ọ na-eme ka waya ndị ahụ gbawaa ma mechie sekit ahụ.

C. Ọ na-esiri ike ijikwa ọdịiche agba dị n'etiti otu. Nsogbu dịka ọkọ, ịcha ọcha na mkpụrụedemede ebipụtara na-apụtakarị n'oge nhazi.

D. Ihe mkpuchi XLPE nke nwere ọkwa iguzogide okpomọkụ nke 150℃ enweghị halogen kpamkpam ma nwee ike ịgafe ule ọkụ VW-1 dịka ọkọlọtọ UL1581 si dị, ebe ọ na-ejigide ihe onwunwe igwe na eletriki dị mma. Agbanyeghị, enwere ụfọdụ ihe mgbochi na teknụzụ mmepụta na ọnụ ahịa ya dị elu.

3. Waya na eriri roba silicone

Mkpụrụ ndụ polima nke rọba silicone bụ usoro yinye nke njikọ SI-O (silicon-oxygen) mepụtara. Njikọ SI-O bụ 443.5KJ/MOL, nke dị elu karịa ike njikọ CC (355KJ/MOL). A na-emepụta ọtụtụ waya na eriri roba silicone site na mmịpụta oyi na usoro vulcanization dị elu. N'etiti ọtụtụ waya na eriri roba sịntetik dị iche iche, n'ihi nhazi molekul pụrụ iche ya, rọba silicone nwere arụmọrụ ka mma ma e jiri ya tụnyere rọba nkịtị ndị ọzọ.

A. Ọ dị oke nro, ọ na-agbanwe agbanwe nke ọma, ọ naghị esi isi ma ọ naghị egbu egbu, ọ naghị atụkwa egwu okpomọkụ dị elu ma nwee ike idi oyi siri ike. Oke okpomọkụ ọrụ ya dị site na -90 ruo 300℃. Roba silicone nwere ike iguzogide okpomọkụ karịa roba nkịtị. Enwere ike iji ya mgbe niile na 200℃ na ruo oge ụfọdụ na 350℃.

B. Ọ dị mma iguzogide ihu igwe. Ọbụna mgbe o kpughechara ogologo oge na ụzarị ultraviolet na ọnọdụ ihu igwe ndị ọzọ, ọdịdị anụ ahụ ya agbanweela naanị obere mgbanwe.

C. Rọba silikọn nwere nnukwu iguzogide ọrịa, ọ na-adịgidekwa n'ọtụtụ okpomọkụ na ugboro ole ọ na-eme.

Ka ọ dị ugbu a, rọba silicone nwere ezigbo iguzogide nnukwu mgbapụta corona na mwepụ arc. Waya na eriri mkpuchi rọba silicone nwere usoro uru ndị a dị n'elu ma ejiri ha mee ihe nke ukwuu na waya ngwaọrụ voltaji dị elu maka telivishọn, waya ndị na-eguzogide okpomọkụ dị elu maka oven microwave, waya maka ihe esi nri induction, waya maka POTS kọfị, ndu maka oriọna, akụrụngwa UV, oriọna halogen, waya njikọ dị n'ime maka oven na fan, ọkachasị n'ọhịa nke obere ngwa ụlọ.

Agbanyeghị, ụfọdụ adịghị ike ya na-ebelatakwa ojiji ya nke ọma. Dịka ọmụmaatụ:

A. Ọ naghị eguzogide ndọda nke ọma. N'oge nhazi ma ọ bụ ojiji, ọ na-enwe ike imebi n'ihi ịpịpụta ike mpụga, ịpịcha na ịpịcha, nke nwere ike ibute obere sekit. Ihe nchebe dị ugbu a bụ ịgbakwunye akwa eriri iko ma ọ bụ eriri polyester dị elu nke a kpara n'èzí mkpuchi silicone. Agbanyeghị, n'oge nhazi ahụ, ọ ka dị mkpa izere mmerụ ahụ sitere na ịpịpụta ike mpụga ruo n'ókè o kwere mee.

B. Ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe ghara ịdị mma bụ okpukpu abụọ, abụọ, anọ. Ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe ghara ịdị mma nwere chlorine. Ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe ghara ịdị mma nke na-enweghị halogen (dịka platinum vulcanizing) nwere ihe achọrọ siri ike maka okpomọkụ gburugburu ebe mmepụta ma dị oke ọnụ. Ya mere, mgbe a na-ahazi eriri waya, a ga-ama ihe ndị a: nrụgide nke wiil nrụgide ekwesịghị ịdị oke elu. Ọ kacha mma iji ihe roba gbochie mgbawa n'oge mmepụta, nke nwere ike ibute nguzogide nrụgide na-adịghị mma.

4. Waya rọba ethylene propylene diene monomer (EPDM) (XLEPDM) nke jikọtara ya na obe

Roba ethylene propylene diene monomer (EPDM) nke a na-ejikọta na Cross-linked bụ terpolymer nke ethylene, propylene na nke na-anaghị ejikọta na conjugated diene, nke a na-ejikọta na cross-linked site na kemịkalụ ma ọ bụ usoro radieshon. Waya EPDM nke a na-ejikọta na Cross-linked roba na-ejikọta uru nke ma waya polyolefin nke a na-etinye na polyolefin na waya roba nkịtị nke a na-etinye na consumer:

A. Dị nro, na-agbanwe agbanwe, na-agbanwe agbanwe, anaghị arapara n'ọnọdụ okpomọkụ dị elu, na-eguzogide ịka nká ogologo oge, na-eguzogide ọnọdụ ihu igwe siri ike (-60 ruo 125℃).

B. Mgbochi Ozone, iguzogide UV, iguzogide mkpuchi eletriki, na iguzogide nchara kemịkalụ.

C. Nguzogide mmanụ na ihe mgbaze yiri nke mkpuchi roba chloroprene nkịtị. A na-eji ngwa extrusion ọkụ nkịtị arụ ọrụ ya, a na-ejikwa njikọ radieshon, nke dị mfe nhazi ma dịkwa ọnụ ala. Waya roba ethylene propylene diene monomer (EPDM) nke ejiri cross-linked cross-linked nwere ọtụtụ uru ndị a kpọtụrụ aha n'elu ma a na-ejikarị ha eme ihe n'ọhịa dịka refrigeration compressor leads, waterproof motor leads, transformer leads, mobile cables in mines, gwongworo, ụgbọala, ngwaọrụ ahụike, ụgbọ mmiri, na waya dị n'ime nke ngwa eletriki.

Isi ihe ọghọm nke waya XLEPDM bụ:

A. Dịka waya XLPE na PVC, ọ naghị eguzogide anya mmiri nke ọma.

B. Nrapara na-adịghị mma na nrapara onwe onye na-emetụta ike nhazi na-esote.

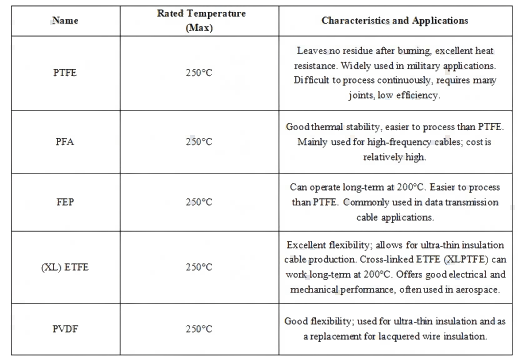

5. Waya na eriri Fluoroplastic

Ma e jiri ya tụnyere waya polyethylene na polyvinyl chloride nkịtị, waya fluoroplastic nwere njirimara ndị a pụtara ìhè:

A. Fluoroplastics ndị na-eguzogide okpomọkụ dị elu nwere nkwụsi ike dị egwu nke okpomọkụ, na-eme ka eriri fluoroplastic nwee ike ịgbanwe na gburugburu okpomọkụ dị elu site na ogo 150 ruo 250 Celsius. N'ọnọdụ ndị na-eduzi nwere otu mpaghara obe, eriri fluoroplastic nwere ike izipu nnukwu ọkụ eletrik a na-ekwe ka ọ dị, si otú a na-agbasa oke ngwa nke ụdị waya a na-ekpuchi ekpuchi nke ukwuu. N'ihi ihe pụrụ iche a, a na-ejikarị eriri fluoroplastic eme ihe maka waya dị n'ime na waya ndu n'ụgbọelu, ụgbọ mmiri, ọkụ ọkụ dị elu, na ngwa eletrọniki.

B. Ezigbo ike ire ọkụ: Fluoroplastics nwere nnukwu oxygen index, mgbe ọ na-ere ọkụ, oke mgbasa nke ire ọkụ dị obere, na-emepụta obere anwụrụ ọkụ. Waya e ji ya mee dabara adaba maka ngwaọrụ na ebe ndị nwere ihe achọrọ siri ike maka ike ire ọkụ. Dịka ọmụmaatụ: netwọk kọmputa, ụgbọ ala ụgbọ oloko, ụgbọala, ụlọ elu dị elu na ebe ndị ọzọ ọha na eze, wdg. Ozugbo ọkụ gbawara, ndị mmadụ nwere ike inwe oge iji pụọ n'enweghị anwụrụ ọkụ dara, si otú a na-enweta oge nzọpụta dị oke ọnụ ahịa.

C. Arụmọrụ eletriki dị mma: Ma e jiri ya tụnyere polyethylene, fluoroplastics nwere obere dielectric constant. Ya mere, ma e jiri ya tụnyere waya coaxial nke ụdị ihe owuwu yiri ya, waya fluoroplastic enweghị mbelata ma dabara adaba maka nnyefe mgbaàmà ugboro ugboro. Taa, ugboro ole ojiji waya na-abawanye aghọwo ihe a na-ahụkarị. Ka ọ dị ugbu a, n'ihi oke okpomọkụ nke fluoroplastics, a na-ejikarị ha eme ihe dị ka waya dị n'ime maka nnyefe na akụrụngwa nkwukọrịta, ihe mkpuchi dị n'etiti ihe na-enye nnyefe ikuku na ihe na-ebufe, na waya vidiyo na ọdịyo. Na mgbakwunye, waya fluoroplastic nwere ezigbo ike dielectric na iguzogide mkpuchi, na-eme ka ha dabara adaba maka iji dị ka waya njikwa maka ngwa na mita dị mkpa.

D. Njirimara mekanikal na kemịkalụ zuru oke: Fluoroplastics nwere ike njikọ kemịkalụ dị elu, nkwụsi ike dị elu, mgbanwe okpomọkụ fọrọ nke nta ka ọ ghara imetụta ya, ma nwee ezigbo iguzogide ịka nká na ike mekanikal. Ọ dịghịkwa emetụta ya site na asịd dị iche iche, alkalis na ihe mgbaze organic. Ya mere, ọ dabara adaba maka gburugburu ebe nwere nnukwu mgbanwe ihu igwe na ọnọdụ mmebi, dị ka petrochemicals, nchacha mmanụ, na njikwa ngwaọrụ olulu mmanụ.

E. Na-eme ka njikọ ịgbado ọkụ dị mfe. N'ihi obere ebe a na-agbaze plastik n'ozuzu, ha na-agbaze ngwa ngwa n'oge okpomọkụ dị elu, na-achọ nkà ịgbado ọkụ nke ọma. Ọzọkwa, ụfọdụ ebe ịgbado ọkụ chọrọ oge ụfọdụ, nke bụkwa ihe kpatara eriri fluoroplastic ji ewu ewu. Dịka waya dị n'ime nke akụrụngwa nkwukọrịta na ngwa eletrọniki.

N'ezie, fluoroplastics ka nwere ụfọdụ ọghọm ndị na-egbochi ojiji ha:

A. Ọnụ ahịa ihe eji emepụta ihe dị elu. Ugbu a, mmepụta ihe dị n'ime ụlọ ka na-adaberekarị na mbubata (Daikin nke Japan na DuPont nke United States). Ọ bụ ezie na fluoroplastics dị n'ime ụlọ etolitela ngwa ngwa n'afọ ndị na-adịbeghị anya, ụdị mmepụta ahụ ka dị otu. Ma e jiri ya tụnyere ihe ndị e si mba ọzọ bịa, enwere obere oghere na nkwụsi ike okpomọkụ na ihe ndị ọzọ zuru oke nke ihe ndị ahụ.

B. Ma e jiri ya tụnyere ihe ndị ọzọ e ji ekpuchi ihe, usoro mmepụta ihe siri ike karị, arụmọrụ mmepụta dị ala, mkpụrụedemede ndị e biri ebi na-adịkarị mfe ịda ada, mfu ahụ dịkwa ukwuu, nke na-eme ka ọnụ ahịa mmepụta ahụ dị elu.

Na mmechi, itinye ụdị ihe mkpuchi niile a kpọtụrụ aha n'elu, ọkachasị ihe mkpuchi pụrụ iche nke okpomọkụ dị elu nke nwere ike iguzogide okpomọkụ karịrị 105℃, ka dị n'oge mgbanwe na China. Ma ọ bụ mmepụta waya ma ọ bụ nhazi eriri waya, ọ bụghị naanị usoro tozuru okè, kamakwa usoro nke ịghọta uru na ọghọm nke ụdị waya a n'ụzọ ezi uche dị na ya.

Oge ozi: Mee-27-2025