Nchịkọta: A kọwara ụkpụrụ njikọ, nhazi, nhazi, usoro na akụrụngwa nke ihe mkpuchi polyethylene silane maka waya na eriri dị mkpirikpi, a kọwakwara ụfọdụ njirimara nke ihe mkpuchi polyethylene silane n'ụzọ ebumpụta ụwa na-ejikọta na ojiji yana ihe ndị metụtara ọnọdụ njikọ nke ihe ahụ.

Okwu ndị dị mkpa: Njikọta Silane; Njikọta eke; Polyethylene; Mkpuchi; Waya na eriri

A na-eji ihe e ji eriri polyethylene nke Silane cross-linked ugbu a eme ihe n'ọtụtụ ebe n'ụlọ ọrụ waya na waya dị ka ihe mkpuchi maka eriri ike dị ala. Ihe e ji emepụta waya na waya cross-linked, na peroxide cross-linking na radieshon cross-linking ma e jiri ya tụnyere akụrụngwa mmepụta achọrọ dị mfe, dị mfe iji, obere ọnụ ahịa zuru oke na uru ndị ọzọ, aghọwo ihe kacha mkpa maka eriri cross-linked dị ala nwere mkpuchi.

1. Ụkpụrụ njikọ njikọ eriri Silane

E nwere usoro abụọ dị mkpa n'imepụta polyethylene silane cross-linked: grafting na cross-linking. N'ime usoro grafting, polima ahụ na-efunahụ H-atom ya na atọm carbon tertiary n'okpuru ọrụ nke onye na-amalite free na pyrolysis n'ime free radicals, nke na-emeghachi omume na - CH = CH2 otu nke vinyl silane iji mepụta polima clapped nwere otu trioxysilyl ester. N'ime usoro cross-linking, a na-ebu ụzọ hydrolyze polima graft n'ihu mmiri iji mepụta silanol, na - OH na-ejikọta na otu Si-OH dị nso iji mepụta njikọ Si-O-Si, si otú a na-ejikọ macromolecules polima.

2. Ihe eji eriri Silane cross-linked na usoro mmepụta eriri ya

Dịka ị maara, e nwere ụzọ mmepụta nke nwere nzọụkwụ abụọ na otu nzọụkwụ maka eriri silane na eriri ha. Ihe dị iche n'etiti usoro nzọụkwụ abụọ na usoro otu nzọụkwụ dị na ebe a na-eme usoro ntinye silane, usoro ntinye na onye nrụpụta ihe eriri maka usoro nzọụkwụ abụọ, usoro ntinye na ụlọ ọrụ mmepụta eriri maka usoro otu nzọụkwụ. Ihe mkpuchi polyethylene nke nwere nzọụkwụ abụọ nke silane nke nwere òkè ahịa kachasị ukwuu bụ ihe a na-akpọ ihe A na B, ihe A bụ polyethylene nke ejiri silane na ihe B mee bụ otu ihe na-akpali akpali. A na-ejikọ isi ihe mkpuchi ahụ na mmiri ọkụ ma ọ bụ uzuoku.

E nwere ụdị ọzọ nke ihe mkpuchi polyethylene nke nwere njikọ abụọ nke silane, ebe a na-emepụta ihe A n'ụzọ dị iche, site n'itinye vinyl silane ozugbo n'ime polyethylene n'oge mmepụta iji nweta polyethylene nwere agbụ silane.

Usoro otu nzọụkwụ nwekwara ụdị abụọ, usoro ọdịnala nke otu nzọụkwụ bụ ụdị ihe eji arụ ọrụ dịka usoro dị na oke nke sistemụ nha kpọmkwem pụrụ iche si dị, n'ime ihe pụrụ iche a haziri nke ọma n'otu nzọụkwụ iji mezue ntinye na mpụta nke isi mkpuchi eriri, na usoro a, enweghị granulation, enweghị mkpa maka isonye na ihe ọkụkụ eriri, site na ụlọ ọrụ eriri iji mezue naanị ya. Ngwaọrụ mmepụta eriri silane a na-ejikọ otu nzọụkwụ na teknụzụ nhazi bụ nke a na-ebubatakarị site na mba ofesi ma dịkwa oke ọnụ.

Ụdị ọzọ nke ihe mkpuchi polyethylene nke silane nke nwere njikọ otu nzọụkwụ bụ nke ndị na-emepụta ihe eriri na-emepụta, bụ ihe niile dị mkpa dịka usoro dị na oke nke ụzọ pụrụ iche nke ịgwakọta ọnụ, kechie ma ree, enweghị ihe A na ihe B, osisi eriri nwere ike ịnọ ozugbo na ihe na-ewepụta iji mezue nzọụkwụ n'otu oge ahụ na-akụnye ma na-ewepụta isi mkpuchi eriri. Ihe pụrụ iche nke usoro a bụ na ọ dịghị mkpa maka ihe pụrụ iche dị oke ọnụ, ebe ọ bụ na enwere ike imecha usoro ịkpụzi silane na ihe na-ewepụta PVC nkịtị, usoro nzọụkwụ abụọ ahụ na-ewepụkwa mkpa ọ dị ịgwakọta ihe A na B tupu a kpụpụ ya.

3. Nhazi nke usoro

Nhazi nke ihe eji eme eriri polyethylene nke silane cross-linked na-abụkarị nke resin ihe eji eme ihe, onye na-amalite ihe, silane, antioxidant, polymerization inhibitor, catalyst, wdg.

(1) Resin ntọala bụkarị resin polyethylene dị obere njupụta (LDPE) nwere ndeksi agbaze (MI) nke 2, mana n'oge na-adịbeghị anya, site na mmepe nke teknụzụ resin sịntetik na nrụgide ọnụ ahịa, ejirila ma ọ bụ jiri obere njupụta polyethylene (LLDPE) mee ihe dị ka resin ntọala maka ihe a. Resin dị iche iche na-enwekarị mmetụta dị ukwuu na ịcha na njikọta n'ihi ọdịiche dị na nhazi macromolecular dị n'ime ha, yabụ a ga-agbanwe usoro ahụ site na iji resin ntọala dị iche iche ma ọ bụ otu ụdị resin sitere na ndị nrụpụta dị iche iche.

(2) Ihe mmalite a na-ejikarị eme ihe bụ diisopropyl peroxide (DCP), isi ihe dị mkpa bụ ịghọta oke nsogbu ahụ, obere ihe iji mee ka silane grafting ezughi oke; oke ihe ga-eme ka polyethylene cross-linking, nke na-ebelata mmiri mmiri ya, elu nke ihe mkpuchi extruded core siri ike, sistemụ siri ike ịpịkọta. Ebe ọ bụ na ọnụọgụ nke ihe mmalite agbakwunyere dị obere ma dị nro, ọ dị mkpa ịgbasa ya nke ọma, yabụ a na-agbakwụnye ya na silane.

(3) A na-ejikarị Silane eme ihe dị ka vinyl unsaturated silane, gụnyere vinyl trimethoxysilane (A2171) na vinyl triethoxysilane (A2151), n'ihi ọsọ ọsọ nke hydrolysis nke A2171, yabụ họrọ ndị ọzọ karịa A2171. N'otu aka ahụ, enwere nsogbu nke itinye silane, ndị na-emepụta ihe eriri ugbu a na-agbalị iru oke ya iji belata ọnụ ahịa, n'ihi na a na-ebubata silane, ọnụ ahịa ya dị oke ọnụ.

(4) Ọgwụ mgbochi oxidant bụ iji hụ na nhazi polyethylene kwụsiri ike na eriri mgbochi ịka nká na mgbakwunye, ọgwụ mgbochi oxidant na usoro nhazi silane nwere ọrụ nke igbochi mmeghachi omume nhazi, yabụ usoro nhazi, mgbakwunye nke anti-oxidant iji kpachara anya, ego agbakwunyere iji tụlee ọnụọgụ DCP ka ọ dabara na nhọrọ ahụ. Na usoro njikọta nzọụkwụ abụọ, enwere ike itinye ọtụtụ antioxidant na batch catalyst master, nke nwere ike ibelata mmetụta na usoro nhazi. Na usoro njikọta otu nzọụkwụ, ọgwụ mgbochi oxidant dị na usoro nhazi dum, yabụ nhọrọ nke ụdị na ọnụọgụ dị mkpa karịa. Ọgwụ mgbochi oxidant ndị a na-ejikarị bụ 1010, 168, 330, wdg.

(5) A na-agbakwunye ihe mgbochi polymerization iji gbochie ụfọdụ usoro njikọta na njikọta nke mmeghachi omume ndị ọzọ na-eme, na usoro njikọta iji tinye ihe na-egbochi njikọta, nwere ike ibelata ihe omume nke njikọta C2C nke ọma, si otú a na-eme ka mmiri nhazi dịkwuo mma, na mgbakwunye, mgbakwunye nke njikọta n'otu ọnọdụ ga-ebu ụzọ site na hydrolysis nke silane na polymerization inhibitor nwere ike ibelata hydrolysis nke polyethylene a gbanyere mkpọrọgwụ, iji melite nkwụsi ike ogologo oge nke ihe nkwụnye.

(6) Ihe ndị na-akpali akpali na-abụkarị ihe ndị sitere na organotin (ma e wezụga njikọ eke), nke a na-ahụkarị bụ dibutyltin dilaurate (DBDTL), nke a na-agbakwụnyekarị n'ụdị masterbatch. N'usoro nzọụkwụ abụọ, a na-etinye graft (ihe A) na catalyst master batch (ihe B) iche iche ma jikọta ihe A na B ọnụ tupu etinye ya na extruder iji gbochie njikọ tupu ihe A. N'ihe gbasara mkpuchi polyethylene silane nke nwere otu nzọụkwụ, a kabeghị tinye polyethylene dị na ngwugwu ahụ, yabụ enweghị nsogbu njikọ tupu ya, ya mere ọ dịghị mkpa ka e tinye catalyst iche iche.

Tinyere nke ahụ, e nwere silanes ndị a gwakọtara agwakọta dị n'ahịa, nke bụ ngwakọta nke silane, ihe mmalite, ihe na-egbochi antioxidant, ụfọdụ mmanụ na ihe ndị na-egbochi ọla kọpa, a na-ejikarịkwa ha eme ihe n'ụzọ njikọ otu nzọụkwụ na osisi waya.

Ya mere, nhazi nke mkpuchi polyethylene silane cross-linked, nke a naghị ewere dị ka ihe dị mgbagwoju anya ma dị na ozi dị mkpa, mana usoro mmepụta kwesịrị ekwesị, dabere na mgbanwe ụfọdụ iji mechaa, nke chọrọ nghọta zuru oke nke ọrụ nke ihe ndị dị na nhazi ahụ na iwu nke mmetụta ha na arụmọrụ na mmetụta ha n'otu n'otu.

N'ọtụtụ ụdị ihe eji eme eriri, a na-ewere ihe eji eme eriri silane (ma ọ bụ nzọụkwụ abụọ ma ọ bụ otu nzọụkwụ) dị ka naanị ụdị usoro kemịkalụ dị iche iche na-eme na extrusion, ụdị ndị ọzọ dị ka ihe eji eme eriri polyvinyl chloride (PVC) na ihe eji eme eriri polyethylene (PE), usoro nhazi granulation bụ usoro ngwakọta anụ ahụ, ọbụlagodi na ihe eji eme eriri kemịkalụ na radiation cross-linking, ma ọ bụ na usoro nhazi granulation extrusion, ma ọ bụ sistemụ mwepụ USB, enweghị usoro kemịkalụ emee, yabụ, ma e jiri ya tụnyere ya, mmepụta nke ihe eji eme eriri silane cross-linked na extrusion mkpuchi eriri, njikwa usoro dị mkpa karịa.

4. Usoro mmepụta mkpuchi polyethylene nke nwere njikọ abụọ nke silane

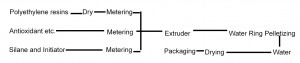

Usoro mmepụta nke mkpuchi polyethylene nke nwere silane nke nwere njikọ abụọ. Enwere ike iji ihe osise 1 gosipụta ya n'ụzọ dị mkpirikpi.

Foto 1 Usoro mmepụta nke ihe mkpuchi polyethylene nke nwere silane nke nwere njikọ abụọ A

Isi ihe dị mkpa n'usoro mmepụta nke mkpuchi polyethylene nke nwere njikọ abụọ nke silane:

(1) Ịkpọ nkụ. Ebe ọ bụ na polyethylene resin nwere obere mmiri, mgbe a na-ewepụta ya n'oge okpomọkụ dị elu, mmiri ahụ na-emeghachi omume ngwa ngwa na otu silyl iji mepụta njikọ, nke na-ebelata mmiri mmiri nke agbaze ma na-emepụta njikọ tupu-cross-link. Ihe e mechara nwekwara mmiri mgbe mmiri jụrụ oyi, nke nwekwara ike ibute njikọ tupu-crosslink ma ọ bụrụ na ewepụghị ya, a ga-akpọkwa ya nkụ. Iji hụ na ịdị mma nke nkụ ahụ dị mma, a na-eji ihe nkụ miri emi.

(2) Ịtụle. Ebe ọ bụ na izi ezi nke usoro ihe eji eme ihe dị mkpa, a na-ejikarị nha nha nke ibu dị n'ime mba ọzọ. A na-atụ ma nye polyethylene resin na antioxidant site na ọdụ nri nke onye na-ewepụta ihe, ebe a na-agba silane na onye na-ebido ihe site na mgbapụta mmiri mmiri n'ime gbọmgbọm nke abụọ ma ọ bụ nke atọ nke onye na-ewepụta ihe.

(3) Ịdọpụ ihe n'ime ihe. A na-emecha usoro ịdọpụ ihe n'ime ihe ndọpụ ihe. Ntọala usoro nke ihe ndọpụ ihe, gụnyere okpomọkụ, njikọta skru, ọsọ skru na ọnụego nri, ga-agbaso ụkpụrụ na enwere ike ịgbaze ihe dị na ngalaba mbụ nke ihe ndọpụ ihe ahụ kpamkpam ma gwakọta ya n'otu aka ahụ, mgbe achọghị ka peroxide gbawaa tupu oge eruo, nakwa na ihe ahụ zuru oke na ngalaba nke abụọ nke ihe ndọpụ ihe ahụ ga-agbaze kpamkpam ma mechaa usoro ịdọpụ ihe ahụ. E gosiri okpomọkụ nke ngalaba ihe ndọpụ ihe nkịtị (LDPE) na Tebụl 1.

Tebụl 1 Okpomọkụ nke mpaghara extruder nzọụkwụ abụọ

| Mpaghara ọrụ | Mpaghara 1 | Mpaghara nke abụọ | Mpaghara nke 3 ① | Mpaghara nke 4 | Mpaghara nke 5 |

| Okpomọkụ P °C | 140 | 145 | 120 | 160 | 170 |

| Mpaghara ọrụ | Mpaghara nke 6 | Mpaghara nke 7 | Mpaghara nke 8 | Mpaghara 9 | Ọnụ anwụ |

| Okpomọkụ °C | 180 | 190 | 195 | 205 | 195 |

①bụ ebe a na-agbakwunye silane.

Ọsọ nke skru extruder na-ekpebi oge obibi na mmetụta ngwakọta nke ihe dị na extruder ahụ, ọ bụrụ na oge obibi dị mkpụmkpụ, peroxide adịghị ezu oke; ọ bụrụ na oge obibi dị ogologo, viscosity nke ihe e si na ya pụta na-abawanye. N'ozuzu, oge obibi nkezi nke granule dị na extruder kwesịrị ịchịkwa na mmalite nkezi nke ugboro 5-10. Ọsọ nri anaghị emetụta naanị oge obibi nke ihe ahụ, kamakwa na ngwakọta na ịkpụcha ihe ahụ, ịhọrọ ọsọ nri kwesịrị ekwesị dịkwa oke mkpa.

(4) Ngwugwu. A ga-etinye ihe mkpuchi silane nke nwere nzọụkwụ abụọ n'ime akpa ngwakọta plastik aluminom n'ikuku kpọmkwem iji wepụ mmiri mmiri.

5. Usoro mmepụta ihe mkpuchi polyethylene nke nwere njikọ otu nzọụkwụ silane

Ihe mkpuchi polyethylene nke silane nke nwere njikọ otu nzọụkwụ n'ihi usoro ya dị na mwepụta nke eriri waya nke isi mkpuchi eriri, yabụ okpomọkụ nke mkpuchi eriri dị elu karịa usoro nzọụkwụ abụọ. Ọ bụ ezie na a tụlere usoro mkpuchi polyethylene nke nwere njikọ otu nzọụkwụ nke silane nke nwere njikọ otu nzọụkwụ n'ịgbasa ngwa ngwa nke onye na-amalite na silane na shear ihe, mana usoro ịkụnye ga-abụrịrị ihe a ga-eji n'aka site na okpomọkụ, nke bụ ụlọ ọrụ mmepụta mkpuchi polyethylene nke nwere njikọ otu nzọụkwụ nke silane nke nwere njikọ otu nzọụkwụ kwusiri ike ugboro ugboro mkpa nke nhọrọ ziri ezi nke okpomọkụ mwepụ, a na-egosi okpomọkụ mwepụ akwadoro na Tebụl 2.

Tebụl 2 Okpomọkụ nke otu nzọụkwụ nke mpaghara ọ bụla ( nkeji: ℃ )

| Mpaghara | Mpaghara 1 | Mpaghara nke abụọ | Mpaghara nke 3 | Mpaghara nke 4 | Flange | Isi |

| Okpomọkụ | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Nke a bụ otu n'ime adịghị ike nke usoro polyethylene silane nke nwere njikọ otu nzọụkwụ, nke a naghị achọkarị mgbe a na-ewepụta waya n'ime usoro abụọ.

6. Ngwa mmepụta

Ngwa mmepụta bụ nkwa dị mkpa maka njikwa usoro. Mmepụta nke eriri silane jikọtara ọnụ chọrọ oke nhazi njikwa usoro dị elu, yabụ nhọrọ nke akụrụngwa mmepụta dị oke mkpa.

Mmepụta ihe mkpuchi polyethylene nke nwere usoro abụọ nke silane. Ngwa mmepụta ihe, nke ugbu a bụ ihe mgbakwunye abụọ nke nwere ihe eji eme ihe na-adịghị arọ nke isotropic n'ụlọ, nke nwere ibu arọ dị iche iche, nwere ike imezu ihe achọrọ maka nhazi usoro, nhọrọ nke ogologo na dayameta nke ihe eji eme ihe eji eme ihe eji eme ihe iji hụ na oge obibi ihe ahụ dị, nhọrọ nke ibu arọ dị iche iche nke ebubata iji hụ na ihe ndị e ji mee ya ziri ezi. N'ezie, enwere ọtụtụ nkọwa gbasara akụrụngwa ndị a ga-elebara anya nke ọma.

Dịka ekwuru na mbụ, a na-ebubata ngwa mmepụta eriri silane nke nwere njikọ otu nzọụkwụ n'ụlọ ọrụ eriri, ndị na-emepụta akụrụngwa dị oke ọnụ, ndị na-emepụta akụrụngwa n'ụlọ enweghị ngwa mmepụta yiri nke ahụ, ihe kpatara ya bụ enweghị mmekorita n'etiti ndị na-emepụta akụrụngwa na ndị na-eme nchọpụta usoro.

7. Ihe mkpuchi polyethylene eke nke Silane

Ihe mkpuchi polyethylene eke nke Silane nke e mepụtara n'afọ ndị na-adịbeghị anya nwere ike ijikọ n'okpuru ọnọdụ eke n'ime ụbọchị ole na ole, na-enweghị uzuoku ma ọ bụ mmiri ọkụ. Ma e jiri ya tụnyere usoro njikọ silane ọdịnala, ihe a nwere ike ibelata usoro mmepụta maka ndị na-emepụta eriri, na-ebelata ọnụ ahịa mmepụta ma na-eme ka arụmọrụ mmepụta dịkwuo elu. Ndị na-emepụta eriri na-amata ma na-eji mkpuchi polyethylene eke nke Silane.

N'afọ ndị na-adịbeghị anya, mkpuchi silane eke nke jikọtara ya na polyethylene etolitela ma mepụta ya n'ọtụtụ buru ibu, yana ụfọdụ uru na ọnụahịa ma e jiri ya tụnyere ihe ndị e si mba ọzọ nweta.

7. 1 Echiche nhazi maka mkpuchi polyethylene jikọtara silane n'ụzọ ebumpụta ụwa

A na-emepụta ihe mkpuchi polyethylene eke nke Silane n'usoro nzọụkwụ abụọ, ya na otu usoro ahụ nke gụnyere resin ntọala, ihe mmalite, silane, antioxidant, ihe mgbochi polymerization na ihe na-akpali akpali. Nhazi nke ihe mkpuchi polyethylene eke nke silane dabere na ịbawanye ọnụego grafting silane nke ihe A na ịhọrọ ihe na-akpali akpali karịa silane mmiri ọkụ cross-linked polyethylene insulators. Ojiji nke ihe A nwere ọnụego grafting silane dị elu yana ihe na-akpali akpali nke ọma ga-eme ka mkpuchi polyethylene nke silane cross-linked jikọọ ngwa ngwa ọbụlagodi na obere okpomọkụ na enweghị mmiri zuru oke.

A na-emepụta ihe ndị dị na A maka ihe mkpuchi polyethylene nke silane ebubatara site na copolymerisation, ebe enwere ike ijikwa ọdịnaya silane n'ọkwa dị elu, ebe mmepụta nke ihe ndị dị na A nwere oke ntinye site na ntinye silane siri ike. A ga-agbanwe ma gbanwee resin ntọala, ihe mmalite na silane ejiri mee ihe na uzommeputa ahụ n'ihe gbasara ụdị na mgbakwunye.

Nhọrọ nke iguzogide na mgbanwe nke dose ya dịkwa oke mkpa, ebe ọ bụ na mmụba nke ọnụego ntinye nke silane na-eduga na mmeghachi omume akụkụ CC na-ejikọ ọnụ. Iji melite mmiri nhazi na ọnọdụ elu nke ihe A maka mmịpụta eriri na-esote, achọrọ oke ihe mgbochi polymerization kwesịrị ekwesị iji gbochie njikọ CC na njikọ tupu njikọta nke ọma.

Tinyere nke ahụ, ihe ndị na-akpali akpali na-arụ ọrụ dị mkpa n'ịbawanye ọnụego njikọta ma kwesị ka a họrọ ha dị ka ihe ndị na-akpali akpali dị irè nke nwere ihe ndị na-enweghị ígwè mgbanwe.

7. 2 Oge njikọta nke silane site na ihe mkpuchi polyethylene nke ekewara ekewa

Oge achọrọ iji mezue njikọta nke mkpuchi polyethylene eke silane n'ọnọdụ okike ya dabere na okpomọkụ, iru mmiri na ọkpụrụkpụ nke oyi akwa mkpuchi. Ka okpomọkụ na iru mmiri dị elu, otú ahụ ka ọkpụrụkpụ nke oyi akwa mkpuchi ahụ si dị nro, oge njikọta dị mkpụmkpụ achọrọ, na ogologo oge nke dị iche. Ebe okpomọkụ na iru mmiri na-agbanwe site na mpaghara ruo na mpaghara na site n'oge ruo n'oge, ọbụlagodi n'otu ebe na n'otu oge ahụ, okpomọkụ na iru mmiri taa na echi ga-adị iche. Ya mere, n'oge eji ihe ahụ eme ihe, onye ọrụ kwesịrị ikpebi oge njikọta dịka okpomọkụ na iru mmiri mpaghara na nke dị ugbu a si dị, yana nkọwapụta nke eriri na ọkpụrụkpụ nke oyi akwa mkpuchi.

Oge ozi: Ọgọst-13-2022